In the competitive landscape of manufacturing, selecting the right ball screw is crucial for optimizing performance. According to industry expert Dr. Emily Carter, “The precision of a ball screw directly impacts machine efficiency.” The demand for high-quality ball screw for sale options has surged, reflecting the need for reliable components in various applications.

Many manufacturers face challenges when sourcing these components. Not all options are created equal, and distinguishing between them can be difficult. Buyers should focus on factors like load capacity and durability. Understanding these elements often leads to better purchasing decisions.

However, even with research, mistakes can happen. Some may prioritize price over quality, often regretting their choices later. The ball screw for sale market is rife with both marked-up and genuinely effective options. It's essential to navigate this landscape carefully to achieve the best results.

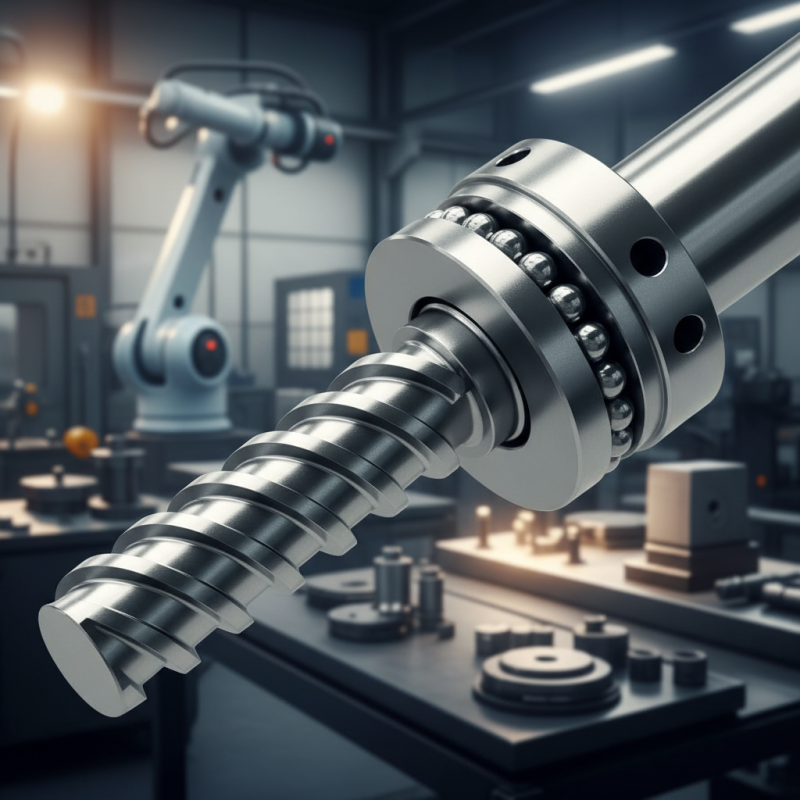

Ball screws are essential components in many machinery applications. They convert rotational motion into linear motion with high efficiency. The design often includes ball bearings that reduce friction. This leads to smoother operation and longer life. When choosing a ball screw, consider lead accuracy and preload. These features impact performance directly.

Key benefits of ball screws include high efficiency and precision. They can handle heavy loads while minimizing wear. However, installation can be tricky. Misalignment may lead to premature failure. Also, the choice of materials affects durability. Not all ball screws are suitable for every application. Some might underperform under specific conditions, which warrants careful evaluation.

Cost is another factor that can complicate the decision. A cheap option may save money upfront. Yet, it could result in increased maintenance costs later. Investing in quality may seem expensive. However, it often pays off in the long run. Each project has unique demands, which require selecting the best ball screw for the job.

When choosing a ball screw for sale, several factors come into play. The load capacity is crucial. You should know the maximum load the screw will bear. It impacts performance significantly. Also, consider the screw's accuracy. A higher precision often ensures better movement and less backlash. This is vital in applications requiring exact positioning.

Material is another important aspect. Different materials affect durability and performance. Stainless steel might offer better corrosion resistance, while a harder alloy can provide higher strength. Additionally, the screw's diameter and lead screw can influence speed and torque capabilities. Selecting the right size can be tricky, as too large or too small might create issues.

Pay attention to the environment where the ball screw will operate. If there are high temperatures or moisture, seals and lubrication should be evaluated. Ignoring these factors can lead to premature failure. Sometimes, the best choice isn’t straightforward. It may require some trial and error to find the optimal solution for your specific needs.

When choosing a ball screw, brand quality is crucial. Several manufacturers dominate the market, offering diverse options to meet different needs. These companies focus on precision and durability. A well-made ball screw enhances the longevity of machinery. A poorly designed one could lead to breakdowns.

Many leading brands emphasize innovation in their products. They often invest in research to improve their designs. This focus may lead to better performance but can also inflate costs. The best choice might not always be the most expensive. Lower-priced options can sometimes provide adequate performance. However, assessing the trade-off between cost and reliability is essential.

It’s vital to consider application requirements when shopping for ball screws. Some designs may offer faster speeds, while others ensure a higher load capacity. Each application has unique demands. Thoroughly evaluate your specific needs. Gathering user feedback can also provide insights into long-term performance. Choosing a ball screw is not a simple task. It requires thoughtful consideration and sometimes, trial and error.

When evaluating ball screw performance, three key metrics stand out: load capacity, efficiency, and backlash. Load capacity refers to the maximum load a ball screw can handle. For instance, a ball screw with a 25 mm diameter can typically support loads up to 5,000 N. This highlights the importance of selecting the right size for your application.

Efficiency is another critical metric. Ball screws can achieve efficiencies between 85% and 95%. Higher efficiencies mean less energy consumption and increased lifespan. A study by the Precision Engineering Society emphasized that even minor differences in efficiency can significantly impact long-term operational costs.

Backlash is the unwanted movement that occurs between the screw and nut. It can affect precision. Options for reducing backlash include double nut designs and preloading. However, increasing preload can compromise performance. A balance must be struck. Consideration of these metrics will help in choosing the optimal ball screw for your specific needs.

When it comes to maintaining the performance of your ball screw, proper care is essential. Regular maintenance can extend its lifespan significantly. Clean the ball screw regularly to prevent dust and debris buildup. Even a small particle can cause wear over time.

Lubrication is vital. Use the right lubricant to ensure smooth operation. Applying too much or too little can lead to problems. Often, users overlook this aspect. A well-lubricated ball screw reduces friction and operates more efficiently.

Check for misalignment frequently. A minor misalignment may result in unwanted wear. Periodically inspect the installation to avoid larger issues down the line. Even a small adjustment can make a noticeable difference. Remember, proactive maintenance is better than reactive repair.